Litharollo tsa lisebelisoa tsa bongaka

Laser Cutting Machine bakeng sa Lisebelisoa tsa Meriana ea Bongaka MPLC6045

TheknolojiPli-arameter:

| Lebelo le Leholo la Tshebetso | 300mm/s(X1);100mm/s(X2);50mm/s(Y);50mm/s(Z);600rpm(θ) | |||

| Boemo bo Nepahetseng | ± 3um (X1) ± 5um (X2); ± 3um (Y); ± 3um (Z) ± 15arcsec (θ) | |||

| Ho Feta Position Ho Nepaha | ±1um(X1);±3um(X2);±1um(Y);±1um(Z);±3arcsec(θ) | |||

| Ho Seha Bophara ba Seam | 20um ~ 30um | |||

| Lisebelisoa tsa mochini | 304&316L&Ni-Ti&L605&Al&Gu&Li&Mg&Fe joalo-joalo. | |||

| Bolelele bo se nang letho ba tube | <2.5m (ts'ehetso ea tšehetso e ka etsoa ka mokhoa o ikhethileng); | |||

| Ho sebetsa lerako botenya | 0 ~ 1.5±0.02 limilimithara; | |||

| Sebaka sa ts'ebetso ea liphaephe | Φ0.3~Φ7.5&Φ1.0~Φ16.0±0.02 limilimithara; | |||

| Lethathamo la tšebetso ea sefofane | 200mm (300mm) * 100mm; | |||

| mefuta ea ho sebetsa | 0~300mm&0~600mm (lihlahisoa tse telele li ka sebetsoa ka likarolo tse arohaneng mokhoa); | |||

| Bolelele ba thepa e setseng | 60 limilimithara | |||

| Mofuta oa laser | Fiber laser; | |||

| Laser wavelength | 1030-1070±10nm; | |||

| matla a laser | 200W&250W&300W&500W&1000W&QCW150W bakeng sa khetho; | |||

| Phepelo ea motlakase ea lisebelisoa | 220V± 10%, 50Hz;AC 25A (sekhechana se seholo sa potoloho); | |||

| Sebopeho sa faele | DXF&DWG&STP&IGS; | |||

| Litekanyo tsa lisebelisoa | 1200mm(&1800mm)x1300mmx1750mm; | |||

| Boima ba lisebelisoa | 1500Kg. | |||

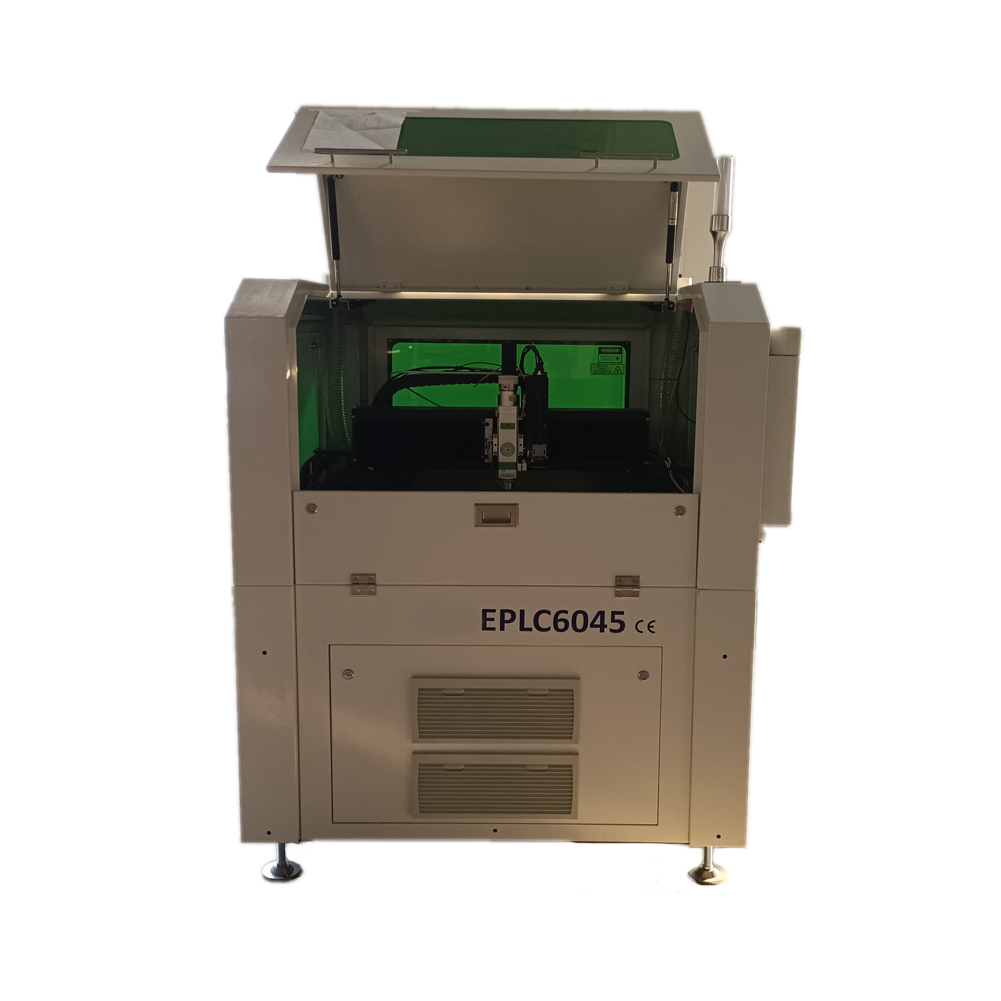

EPLC6045

Ho ikamahanya le maemo ho matla

① Ka ho itšeha ka laser, ho itšeha le ho phunya le ho phunya le ho betla le tse ling tse ntle tsa machining

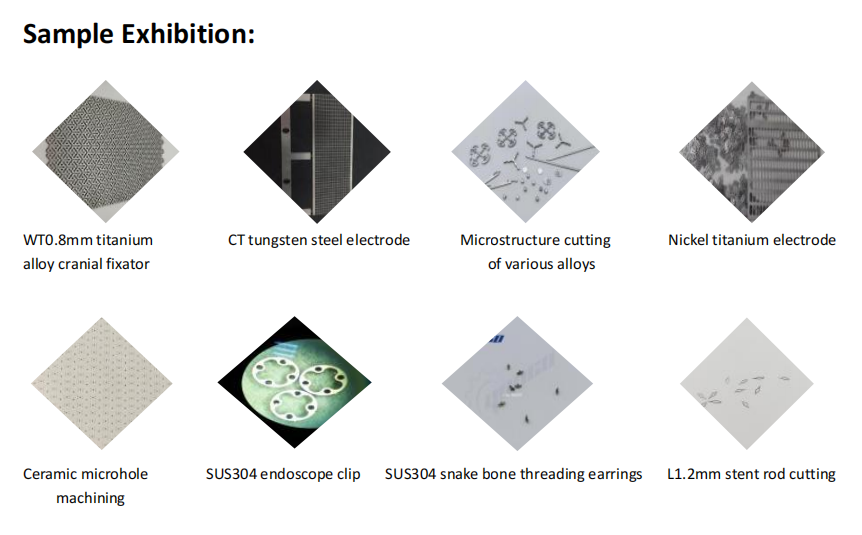

②Can mochini 304&316L&Ni-Ti&L605&Li&Mg&Al&Cu&Fe&Ceramic le lisebelisoa tse ling

③Na mochini oa sefofane le lisebelisoa tse kobehileng holim'a metsi

④Fana ka maemo a habeli & pono ea mochini & ho amohela le ho koala sekheo le ho kenya le ho laolla sistimi & ho beha leihlo ka matla le mesebetsi e meng e ts'oanang.

⑤ E na le hlooho e iketselitseng nako e telele le e khuts'oane ea laser e sehang hlooho e bohale le molomo o bataletseng & e tsamaisana le hlooho e fumanehang khoebong ea laser.

⑥E na le sistimi e iketselitseng ea 2D & 2.5D & 3D CAM ea laser micromachining

Latela mohopolo oa moralo oa ergonomics, o bobebe ebile o khuts'oane

Sebaka sa kopo:

Laser micromachining ea lisebelisoa tsa ho buoa le tsa masapo tse kang endoscope e thata & ultrasonic scalpel & endoscope& stapler & suture device & soft drill & planer & puncture nale & nose drill

Mochine o nepahetseng haholo:

①Bophara bo bonyenyane ba seam: 18 ~ 30um

②Ho nepahala ha mochini o phahameng: ≤ ± 10um

③Boleng bo botle ba ho seha: ha ho burr le ho seha ho boreleli

④Bokhoni bo phahameng ba mochini: ho seha hanngoe ka lebota le lehlakoreng le le leng le mochini o tsoelang pele oa phepelo

Moqapi o feto-fetohang

① Latela mohopolo oa moralo oa ergonomics, o bobebe ebile o khuts'oane

②Fana ka ts'ebetso ea boikhethelo ea sistimi ea pono ea mochini ho lekola ts'ebetso ea machining ea laser ka nako ea nnete.

③ Ts'ebetso ea software le ea Hardware e tsamaellana habonolo, e ts'ehetsa tlhophiso ea ts'ebetso ea motho ka mong le taolo e bohlale ea tlhahiso.

④Tsehetsa moralo o mocha ho tloha boemong ba karolo ho isa boemong ba sistimi

⑤ Taolo ea mofuta o bulehileng le sistimi ea laser micromachining e bonolo ho sebetsa le sebopeho se hlakileng

Litaba tse amanang le tsona

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur