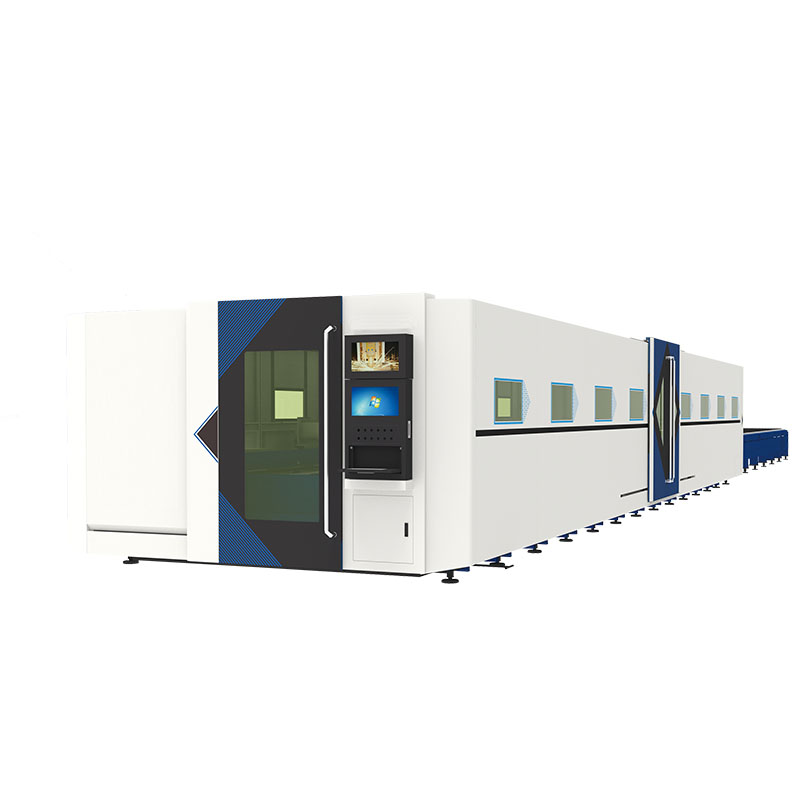

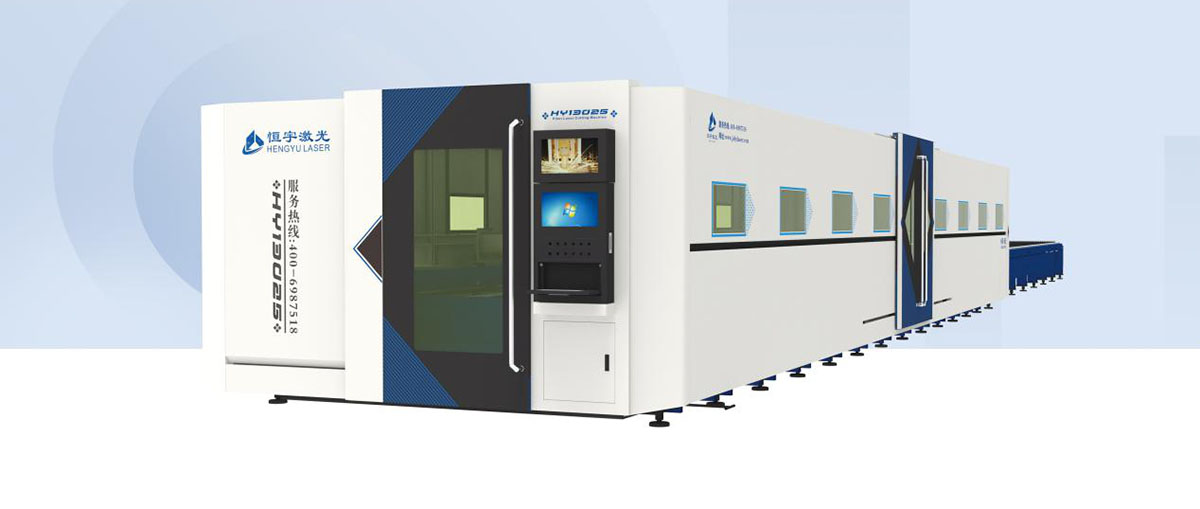

Mechini

Mochini oa ho roala le ho theola othomathike oa laser pipe o nang le li-chucks tse tharo

| Bolelele ba phala | 6000mm / 8000mm / 12000mm |

| Pipe bophara | 20mm-200mm / 30mm-630mm |

| Boholo ba ho fepa | 800mm*800mm*6000mm / 800mm*800mm*8000mm |

| matla a laser | 1000W/1500W/2000W/2500W/3000W/4000W |

| Mofuta oa pipe o sebetsang | Pipe e chitja, peipi ea lisekoere, peipi e khutlonnetsepa, peipi e elliptical, mofuta oa D, mofuta oa T, tšepe ea mofuta oa H, tšepe ea kanale, tšepe ea angle, jj. |

| Lisebelisoa tse sebetsang | Tšepe e sa hloekang, tšepe ea carbon, phala e entsoeng ka masenke, phala ea koporo, phala ea aluminium, motsoako oa aluminium |

| Letšoao la laser | Leseli / IPG / Raycus |

| morwalo | 25 lik'hilograma / M |

| Pheta ho nepahala ha maemo | ± 0.03 limilimithara |

| Ho potlakisa | 1.5g |

1.Pipe e chitja, phala e khutlonnetsepa, phepelo e itirisang ka botlalo, phepelo e kholo ea bongata, boima bo boholo ba 2.5T.

2.Sistimi e tsoetseng pele ea chuck clamping, chuck self centering, lokisa boholo ba matla a ho koala ho ea ka sebopeho sa profil, fana ka tharollo e felletseng ea phala e nang le marako a masesaane, lebelo le phahameng ho fihla ho 150rpm, chuck e tiisitsoe, thibela ho seha tšepe ea tšepe. bokahare, e tsitsitse ebile e ka tšeptjoa.

3.Tšehetso ea thepa ea ho phahamisa e phaphametseng, bophahamo ba tšehetso bo ka fetoloa ka mokhoa o itekanetseng le ka nako ea sebele, ho ea ka phetoho ea boemo ba phala, ho etsa bonnete ba hore karolo e ka tlaase ea phala e lula e sa arohane ho tloha holimo ho sefate sa tšehetso, 'me e sebetsa e le matla. tšehetso ea phala.

4.Sesebelisoa sa ho amohela ka mokhoa o itekanetseng se ka latela tšehetso ea ho phahamisa, ho tšoara thepa le ho kenya ka basketeng;tšehetso e phaphametseng e laoloa ke servo motor, e ka fetola ka tsela e iketsang ho ea ka bophara phala ka potlako, ho boloka nako ea clamping, ho netefatsa concentricity le ho fokotsa ho sisinyeha ha phala.

5.Khethollo ea seam ea welding e ka beha boemo ba seam seam ea phala, ho etsa bonnete ba hore sebaka sa ho qala sa ho itšeha se hole le weld nakong ea ts'ebetso, e le ho qoba bothata ba ho phatloha ha lesoba ho weld.

6.0 tailing cutting wtih three chucks, complements and cutting head offside cutting and groove process, ho fihlela mohatla ka hare ho 50-80mm.

7.Ts'ebetso e bonolo ea mokhoa oa ho haha sehlaha, ho boloka litšenyehelo tsa basebetsi, e le hore litšoantšo li se ke tsa hlola li khathatsa bareki.

1.Ho ema betheng e matla, e tiileng, e entsoeng hantle, ho seha poleiti ea tšepe e teteaneng le tšepe e se nang ferrous, ho potlakisa 1.5g, ho ka khaola poleiti ea tšepe ea 35mm, poleiti ea tšepe ea 50mm le poleiti ea aluminium ea 12mm ka lebelo le phahameng.

2.3 metres, 4 metres, 6 metres le 8 metres ho hloa mofuta oa phapanyetsano tafoleng, phapanyetsano e potlakileng, e ntlafatsa ts'ebetso.

3.Sebopeho se koahetsoeng ka ho feletseng, ho fana ka tšireletso ea tšireletso ea botho, le ho qoba kotsi e bakoang ke mahlaseli a khanyang a sa bonahaleng le motsamao oa mochine oa mochine.Thepa e ka ba braking ea tšohanyetso ho thibela ts'oaetso ea motlakase.

4.Ho tjheseletsa poleiti ea tšepe, ho chesoa ha mocheso o phahameng, botsofali ba ho thothomela, bethe e senyehang, litšenyehelo tse tlase tsa tlhokomelo.

5.Seporo se tsoang kantle ho naha le se fokotsang motlakase oa servo, se fokotsang khokahano ea flange, rack ea terene e nang le lubrication habeli.

6.Seporo sa seporo sa seporo ke karolo e felletseng ea tšepe, ka nako e 'ngoe e behiloe ka sesebelisoa sa mochini oa CNC, e le ho netefatsa ho nepahala.Setsi sa setopo se phahameng se kentsoe, 'me se ke ke sa senyeha le ka mor'a nako e telele.

7.Ho nepahala ha mochini o fokotsang thepa e tsoang kantle ho naha ho tsoa Jeremane ho ka fihla metsotso e 3-1 ea arc, mokhoa oa ho kenya disk eccentric le mochini oa phallo ea gear o tsitsitse ebile oa tšoarella.

Litaba tse amanang le tsona

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur