Handheld laser tjheseletsa e le laser sebetsa thekenoloji, laser tjheseletsa thekenoloji e se e sebelisoa ho tjheseletsa ea likarolo tse nyenyane tšesaane ho tloha ka 1964. Ka tsoelo-pele e potlakileng ea indasteri ea likoloi le ntlafatso e tsoelang pele ea litlhoko tsa batho, ho finyella litlhoko tsa polokeho, tshireletso ya tikoloho, le paballo ya eneji, le ho fihlela boiketsetso, ho tenyetseha le ntshetsopele e bohlale ya tlhahiso ya dihlahiswa tsa welding, thekenoloji ya welding ya laser e sebeditswe lebaleng la tlhahiso ya mmele ho tloha ka bo-1980.Ho ea ka lipalo-palo tse amehang, 50% ~ 70% ea likarolo tsa likoloi linaheng tse tsoetseng pele tsa indasteri tsa Europe le Amerika li sebetsoa ka laser, haholo-holo welding ea laser le ho itšeha.Laser welding e fetohile mokhoa o tloaelehileng oa tlhahiso ea likoloi.

Molao-motheo oa ts'ebetso

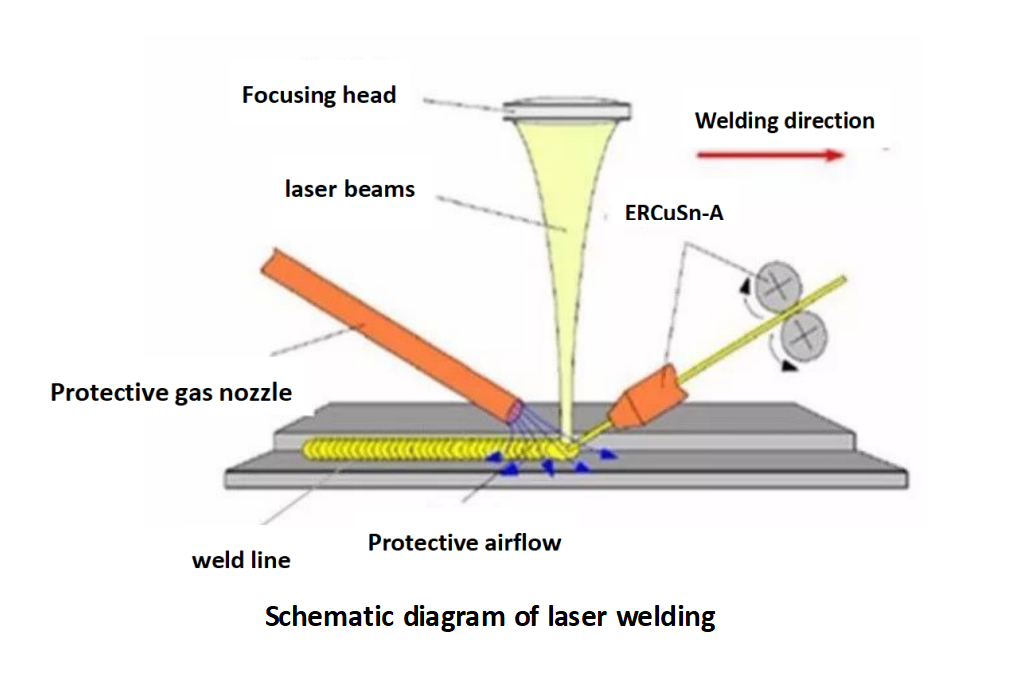

Molao-motheo oa laser welding ke hore lebone la laser le hlahisoang ke jenereithara ea laser le tsepamisitsoe holim'a terata ea welding bakeng sa ho futhumatsa e le hore terata ea welding e futhumale ebe e qhibiliha, poleiti ea tšepe 'meleng oa koloi e kolobisitsoe, lekhalo pakeng tsa manonyeletso a tšepe a tlatsitsoe, 'me seam sa welding se thehoa ho fihlela qetellong ho finyella kamano e ntle.Khokahano ea brazing lipakeng tsa terata ea koporo le poleiti ea tšepe e thehoa kamora ho tjheseletsa.Mohala oa tjheseletsa oa koporo le poleiti ea tšepe ke likarolo tse fapaneng, 'me lera la ho tjheseletsa le entsoeng ke bona ke ho kopana ha likarolo tse peli tse fapaneng ka mor'a mocheso o phahameng.Ha ho bapisoa le mokhoa oa khale oa ho tjheseletsa, mokhoa ona oa ho tjheseletsa o na le boleng bo betere ba ho tjheseletsa, lebelo le lebelo le matla a phahameng a karolo ya welding.

Melemo ea ho tjheseletsa laser ka letsoho ke e latelang:

1.Small mocheso ameha sebaka.Mocheso oa ho kenya o ka fokotsoa ho bonyane bo hlokahalang, 'me sebaka se amehileng ke mocheso se senyenyane, kahoo ho senyeha ha mocheso ho fokotsehile.

2.Ho se kopane.Ho tjheseletsa ho bonahalang, ho tjheseletsa ho sa kopane, ha ho hlokahale ho sebelisa li-electrode, ha ho na matšoenyeho mabapi le tšilafalo ea li-electrode kapa tšenyo, 'me tšebeliso le deformation ea mochine li ka fokotsoa.

3.Lebala la laser le bonolo ho tsepamisa maikutlo, ho lumellana le ho tataisoa ke lisebelisoa tsa optical, li ka behoa sebakeng se loketseng ho tloha mosebetsing, 'me li ka tataisoa pakeng tsa mechine, lisebelisoa kapa litšitiso tse pota-potileng mosebetsi.

4.The laser beam e ka tsepamisoa sebakeng se senyenyane haholo 'me e ka iketsetsa likarolo tse nyenyane le tse haufi-ufi.

5.Ho bonolo ho lemoha tjheseletsa e itekanetseng ka lebelo le phahameng ka ho laola lipalo.

Nako ea poso: Dec-23-2022