Tharollo e nepahetseng ea 3c

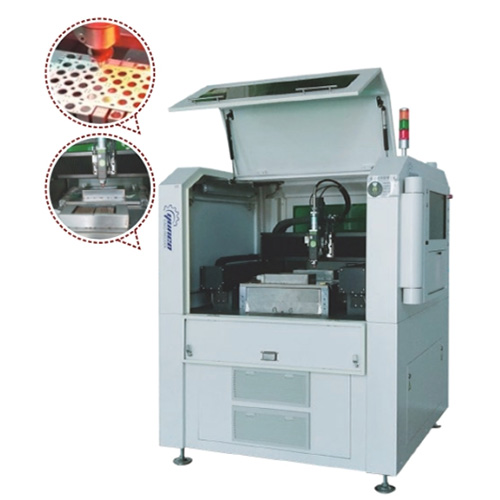

ECLC6045 Precision Laser Cutting Machine bakeng sa Lisebelisoa tsa Hard Brittle

Mochini o nepahetseng oa ho itšeha oa laser bakeng sa lisebelisoa tse thata le tse brittle

Mochini o thata le o brittle oa ho itšeha ka mokhoa o nepahetseng oa laser ke mofuta oa mochini o nepahetseng oa laser, o sebelisetsoang ho itšeha, ho cheka, ho cheka, ho hlaba le tse ling tsa laser micromachining ea sefofane se thata le se brittle kapa lisebelisoa tse tloaelehileng tsa holim'a metsi, joalo ka ho etsa lesale la MIM. Sekoaelo sa mohala se entsoeng ka ceramic, ho roala poleiti ea ceramic, ho cheka sapphire, ho seha le ho theha lakane ea tungsten, ho ngola le ho etsa zirconia ceramic, joalo-joalo Thepa e tsoetse pele ka moralo, e nang le sistimi e bulehileng ea software ea CNC, e amohela theknoloji ea ntlafatso ea ts'ebetso ea modular, e kentsoeng. Laeborari ea theknoloji ea laser processing le sistimi ea taolo ea li-axis tse ngata, e bulehileng haholo, botsitso bo botle le ts'ebetso e bonolo.

Tekheniki Parameters

| Lebelo le phahameng la ts'ebetso | 1000mm/s(X) ;1000mm/s(Yl&Y2) ;50mm/s(Z); |

| Ho beha ho nepahala | ±3um (X) ±3um (Y1&Y2) ±5um (Z); |

| Ho nepahala ha maemo a pheta-phetoang | ± lum (X) ; ± lum(Y1&Y2) ;±3um(Z); |

| Lisebelisoa tsa mochini | Alumina & zirconia & aluminium nitride & silicon nitride & Diamond & Sapphire & Silicon & gallium arsenide & tungsten tšepe, joalo-joalo; |

| Botenya ba lerako la thepa | 0 ~ 2.0±0.02mm; |

| Lethathamo la mechine ea lifofane | 300mm * 300mm; (tšehetso bakeng sa litlhoko tse kholo tsa sebopeho) |

| Mofuta oa laser | Fiber laser; |

| Laser wavelength | 1030-1070±10nm; |

| matla a laser | CW1000W&QCW150W& QCW300W& QCW450W bakeng sa khetho |

| Phepelo ea motlakase ea lisebelisoa | 220V± 10%, 50Hz;AC 20A (sekhechana se seholo sa potoloho); |

| Sebopeho sa faele | DXF, DWG; |

| Litekanyo tsa lisebelisoa | 1280mm * 1320mm * 1600mm; |

| Boima ba lisebelisoa | 1500Kg. |

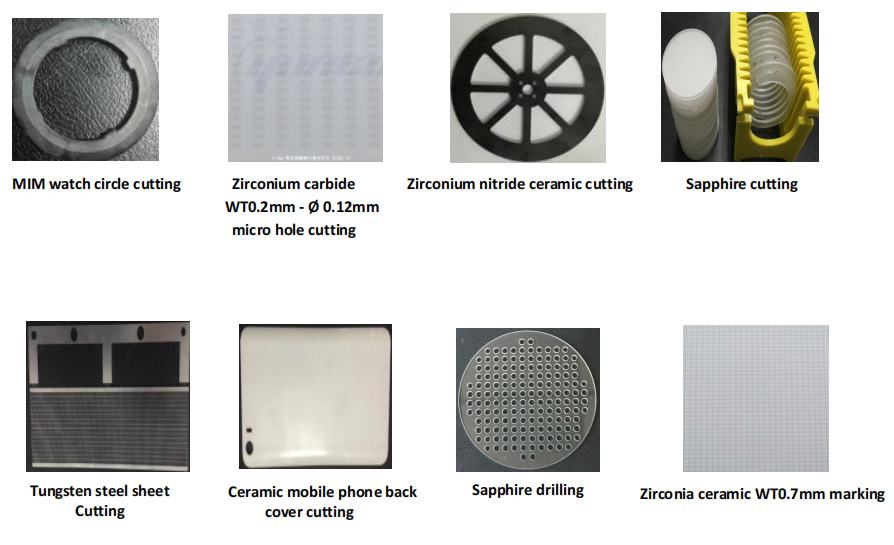

Mohlala oa Pontšo

# Laser micromachining ea lirafshoa, safire, daemane le tšepe ea calcium, boima bo phahameng le sefofane se phahameng sa brittleness le lisebelisoa tse tloaelehileng tse kobehileng.

Ho sebetsa ka nepo ka holimo

Sekhahla se senyenyane sa seam bophara: 15 ~ 30um

Ho nepahala ha mochini o phahameng: ≤ ± 10um

Boleng bo botle ba ho cheka: ho cheka ho boreleli, sebaka se senyenyane se amehileng ke mocheso, li-burr tse fokolang le ho phunyeha ka bohale < 15um

Tokiso ea boholo: bonyane boholo ba sehlahisoa ke 100um

Ho ikamahanya le maemo ho matla

1.Ho ba le bokhoni ba ho itšeha ka laser, ho cheka, ho slotting, ho tšoaea le litsebo tse ling tse ntle tsa ho sebetsa bakeng sa lifofane le lisebelisoa tse kobehileng holim'a metsi.

2.Can mochini oa alumina, zirconia, aluminium nitride, silicon nitride, taemane, safire, silicon, gallium arsenide le tungsten tšepe.

3.E na le sethala sa motsamao se ikemetseng se iketselitseng habeli, sethala sa granite, sethala sa aluminium alloy granite bakeng sa khetho.

4.Fana ka mosebetsi oa boikhethelo, joalo ka liteishene tse habeli & Visual Positioning & mokhoa oa ho fepa le oa ho theola thepa & tlhahlobo e matla joalo-joalo.

5.E na le bolelele bo bolelele le bo bokhutšoane bo iketselitseng, molomo o bohale le nozzle e bataletseng hlooho e ntle ea laser

6.E na le mokhoa oa ho amohela thepa ea modular le mokhoa oa ho tlosa lerōle

7.Fana ka foreimi e itlhophileng ea tsitsipano le foreimi e tsitsitseng ea tsitsipano & vacuum adsorption & plate ea mahe a linotši, joalo-joalo.

8.E na le sistimi e iketselitseng ea 2D & 2.5D & 3D CAM ea laser micromachining.

Moqapi o feto-fetohang

1.Latela mohopolo oa moralo oa ergonomics, o bobebe ebile o khuts'oane

2.Software e feto-fetohang le tlhophiso ea tšebetso ea hardware, e ts'ehetsang tlhophiso ea ts'ebetso ea motho ka mong le taolo e bohlale ea tlhahiso

3.Tsehetsa moralo o motle oa ntlafatso ho tloha boemong ba karolo ho isa boemong ba sistimi

Taolo ea 4.Open & laser micromachining software e bonolo ho sebetsa & segokanyimmediamentsi sa sebolokigolo

Setifikeiti sa tekheniki

ka CE

ISO9001

Setšoantšo sa IATF16949

Litaba tse amanang le tsona

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur