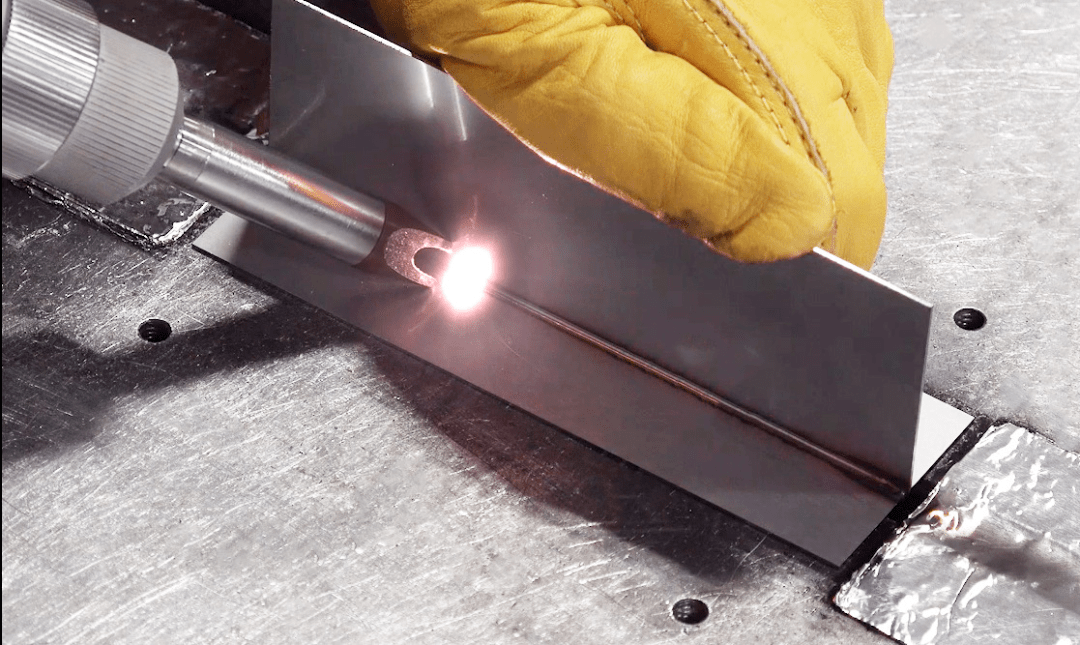

Joalo ka ha motho e mong le e mong ea leng selikalikoeng sa welding a tseba, welding ea setso ea MIG le TIG e sebelisoa haholo indastering.Leha ho le joalo, mekhoa ena e 'meli ea ho tjheseletsa e na le litlhoko tse phahameng bakeng sa litsebo tsa li-welders.Li-welders li hloka ho qeta nako e ngata li tseba hantle lintho tsa bohlokoa tsa welding.Sistimi ea laser handheld welding e etsa hore ho be bonolo haholo hore batho ba tloaelehileng ba qale, mme ba ka fumana litlamorao tsa boleng bo holimo habonolo.

Re entse letoto la liteko tsa ts'ebetso ho mohlala oa welding oa laser handheld welding, joalo ka tsitsipano, ho kobeha, le metallography.Ka mor'a moo, a re boneng hore na boleng ba tjheseletsa ea tsamaiso ea letsoho ea letsoho ea laser e ka fetisa tlhahlobo ka katleho.

01, Likarolo

• Matla a laser a fihla ho 1500W.Bakeng sa lisebelisoa tse fapaneng le botenya, litlhophiso tse ntle ka ho fetisisa tsa welding li ka khethoa ka potlako ka kotola e hlakileng ea tokiso.

• Sebelisa mekhoa e 74 e bolokiloeng esale pele le e hlalositsoeng ke mosebedisi ho thusa li-welder tse qalang ho tseba tšebetso ea ho cheselletsa ka lihora tse 'maloa tsa koetliso.

• Khetha mokhoa oa ho boloka ho fana ka matla a phahameng a fihlang ho 2500W, ho ba le bokhoni bo matla ba ho tjheseletsa.

• Mosebetsi o mocha oa ho hloekisa o eketsoa motheong oa pele, o ka tlosang oli, mafome le ho roala ka potlako le ka mokhoa o bonolo pele ho tjheseletsa, le ho tlosa masala a holim'a metsi le ho fetoha ha oxidation ka mor'a ho cheselletsa.Weld e ntle e ka fumanoa ntle le tšebeliso ea li-abrasives kapa lik'hemik'hale, ho boloka litšenyehelo tse eketsehileng le nako.

02, lisebelisoa tse chesehang

| Material Science | BotenyaSingle side weld | BotenyaWeld ka mahlakoreng a mabeli |

| ts'epe e sa beng le mabali | 4mm | 10 limilimithara |

| tshepe e bonolo | 4mm | 10 limilimithara |

| aluminium | 4mm | 10 limilimithara |

| koporo | 1mm | 2mm |

03 、 Melemo

• Ho tjheseletsa ho phahameng: ka makhetlo a 4 ka potlako ho feta ho tjheseletsa ho tloaelehileng, ho eketsa tlhahiso le ho fokotsa litšenyehelo tsa workpiece ka 'ngoe.

• Boleng bo phahameng ba tjheseletsa: Thepa e teteaneng e tenyang ka tsela e tshwanang, disebediswa tse tshesane, le dimetale tse bonahatsang ntle le deformation, undercut, kapa burn-through, mme sebaka se anngoeng ke mocheso se senyane haholo.

• Ho bonolo ho e sebelisa: Ho beha lintho ka tsela e bonolo, ho ithuta le ho sebetsa ka ho tepella maikutlo, ho ka khona ho hlokomela litšepe tsa boleng bo phahameng le ho hloekisa.

• Ponahalo ea weld: Letheba la oli, mafome le ho roala li tla tlosoa pele ho tjheseletsa, 'me masalla a bokaholimo le oxidation discoloration a tla tlosoa ka mor'a ho cheselletsa, ho boloka nako le litšenyehelo tsa ho sebelisa li-abrasive kapa lik'hemik'hale.

• Mefuta e mengata ea lisebelisoa: Litšepe tsa botenya bo fapaneng, likarolo tse tšesaane haholo, li-welding tsa koporo, le lisebelisoa tse nang le conductivity e fapaneng.

• Swing welding: Bophara ba swing bo fihla ho 5mm, ho ntlafatsa bokhoni ba ho tjheseletsa le bophahamo ba weld bo botle.

• Tšireletseho ea opereishene: Li-sensor tsa mekhahlelo e mengata le lisebelisoa tsa tšireletso tse hokahaneng

| Mokhoa oa setso oa ho cheselletsa | Ho chesoa ka laser | |

| lebelo la ho tjheseletsa | tloaelehileng | Ka makhetlo a fetang 4 ka potlako |

| boleng ba tjheseletsa | E ipapisitse le boiphihlelo ba opareitara | Phello ea boleng bo phahameng |

| Bothata ba ho ithuta | ka thata | Ho bonolo ho e sebelisa |

| Litokisetso bakeng sa welding workpiece | Tokisetso e bohlokoa ebile e na le mathata | Tokisetso e fokolang le e bonolo |

| Tokisetso ea workpiece pele tjheseletsa Material tenyetseha | E fokotsoe ke phetoho ea lintho tse bonahalang | E pharaletseng, ha ho hlokahale hore e behe |

| Sebaka se amehileng ke mocheso | e kgolo | Nyenyane |

| Ho kobeha le deformation | Ho bonolo haholo ho holofatsa | Ha ho bonolo ho holofala |

| Swing welding | Ha ho letho | Swing bophara ho fihlela ho 5mm |

04. Litekanyetso tsa tekheniki

| matla a laser | Matla a phahameng a phahameng | matla | Mokhoa oa ho boloka matla | Ho hloekisa bopharale bolelele | Bolelele ba swingle khafetsa | Litekanyo(L *W *H) | boima |

| 1500W | 2500W | 220V,24A | 74 | 15 limilimithara | Ho fihlela ho 300H,ho fihlela ho 5mm | 641*316*534mm | 53KG |

Re ka bona hore ts'ebetso ea laser e ts'oaroang ka letsoho e phahame haholo ho feta ea setso ea TIG le welding ea MIG likarolong tse ngata.Mohlomong haufinyane, sebaka sa welding e tla ba lefats'e la welding ea letsoho ea laser.

Nako ea poso: Nov-30-2022