Ka ts'ebetso ea nts'etsopele ea liindasteri Chaena, batho ba lula ba fana ka litlhoko tse phahameng bakeng sa boleng ba tjheseletsa ba ho tjheseletsa ka letsoho.Mokhoa oa ho cheselletsa letsoho oa argon oa setso ha o sa khona ho fihlela litlhoko tse phahameng tsa batho bakeng sa boleng le ts'ebetso ea welding.

Tekanyetso ea ho lekanya boleng ba mochini oa tjheseletsa o ts'oaroang ka letsoho o ka mahlakoreng 'ohle.Ka lehlakoreng le leng, ke boleng ba tjheseletsa.Ka lehlakoreng le leng, ts'ebetso ea mochini,

1.Welding boleng

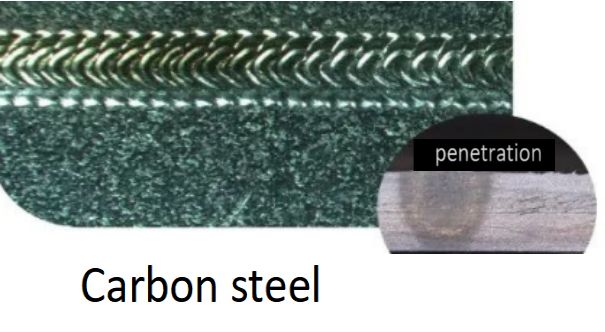

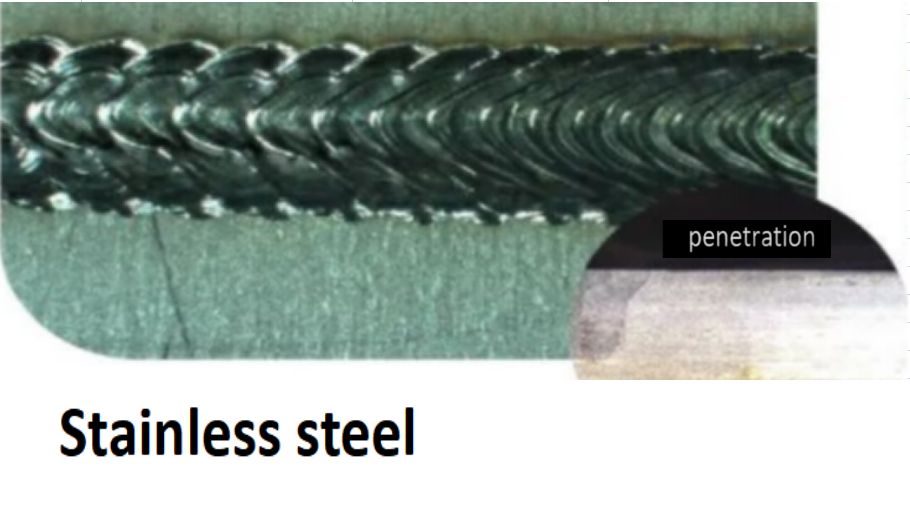

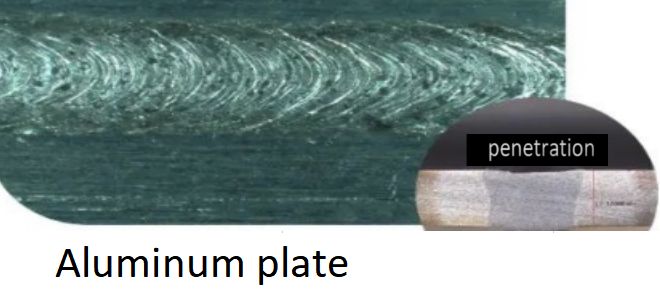

Lebelo la welding la argon arc welding le lieha ebile le bonolo ho hlahisa deformation;Sesebelisoa sa laser se tšoaroang ka letsoho se potlakile, ha se bonolo ho holofala, weld e tiile haholo, ntle le leqeba la welding, motsoako oa welding o motle ebile o boreleli, 'me ts'ebetso e tsitsitse ebile e ka tšeptjoa.

Litalenta tse phahameng tsa tekheniki tsa k'hamphani indastering li ikemiselitse ho etsa mahlale a macha le ho pheta-pheta lisebelisoa tsa welding tsa laser tse tšoaroang ka letsoho, ho khothaletsa ntlafatso ea theknoloji ea welding, ho fa bareki lisebelisoa tsa boleng bo holimo tse tšoaroang ka letsoho tsa laser, le ho tlisa boiphihlelo bo bocha.Lebelo la tjheseletso la tjheseletso e tshwarwang ka letsoho la laser le lebelo ka makgetlo a 5 ho isa ho a 10 ho feta la tjheseletsa ya setso.

| Lintho tse bonahalang | Ho kenella | Lebelo |

| Ts'epe e sa beng le mabali | 4mm | 7mm/s |

| Tšepe ea Carbon | 4mm | 6mm/s |

| Aluminium | 3mm | 7mm/s |

| Leqephe la Galvanized | 4mm | 7mm/s |

| Koporo | 3mm | 8mm/s |

| Koporo | 1mm | 8mm/s |

2.Boleng ba mochini - tlhahlobo ea lera ka lera

Pele o tloha fekthering, mochini o mong le o mong oa tjheseletsa o fetisitse tlhahlobo ea botsofali e bobebe ea lihora tse 72 (35 ° C), le tlhahlobo ea botsitso ba matla a 99%.Laser chip e na le bophelo ba ts'ebeletso ea lihora tse 100,000.Sehlahisoa se fetile tlhahlobo e felletseng ea liteko / liteko tsa EMC, 'me se tsitsitse ebile se tšoarella.

Nako ea poso: Nov-15-2022